Working principle:

Heat pump is a device that collects and utilizes the heat energy contained in the air. It is called air energy heat pump technology. The available equipment developed by air energy heat pump technology includes air energy heat pump dryer, etc. Yilino mango dryer uses the inverse Cano principle to absorb the free heat in the air by inputting a small amount of electric energy and transfer it to the drying room (inputting one degree of electric energy to generate four degrees of electric heat energy) to realize the temperature rise of the drying room, and cooperate with the corresponding dehumidification and dehumidification equipment to realize the material drying. It consists of compressor, condenser (heater), throttling device (electronic expansion valve), evaporator (heat absorber) and other devices to form a refrigeration cycle system.

Application scope of heat pump dryer:

Because the heat pump dryer is not affected by the external environment, weather, season and climate, it can work continuously for 24 hours, and can well guarantee the quality, color, appearance and effective composition of the dried products, It can meet the drying requirements of different products, so it can be widely used in the drying of agricultural and sideline products, aquatic products, meat products, traditional Chinese medicine, fruits and vegetables, food, grain, seeds, clothing, tea, paper and other fields.

Advantages of air energy heat pump dryer:

1. High efficiency

The equipment adopts the fully sealed structure and inner hot air circulation, which greatly shortens the material drying time and ensures the product output. Moreover, it is easy to install and remove, with less floor area, and can be installed indoors and outdoor

2. energy saving

The equipment can absorb a large amount of heat in the air ,it only needs a small amount of electric energy consumption, which is only 1 / 4 of the electric heater. Compared with coal, oil and gas dryers, it can save about 70% of the operating cost.

3. environmental protection

No waste heat, waste gas, combustibles and emissions will be generated during the operation of the equipment, and there is no risk of flammability, explosion, poisoning, short circuit and other hazards that may exist in the traditional dryer.

4. safety

The equipment is equipped with multiple safety protection functions, such as phase sequence protection, phase loss protection, overload protection, high and low voltage protection, etc. the water and electricity are completely separated and there is no potential safety hazard.

5. Health

Its closed cyclet structure is very important for food, medicine or biological products to avoid impurity pollution caused by gas exchange with the outside world.

6. Automatic

The equipment is free of manual operation, no special person is required to take care of it, the material does not need to be turned over, the intelligent automatic control drying time and dehumidification time are stable and easy to operate. According to the characteristics of the material, the material can be dried at different temperatures in multiple time periods, and 10 drying process parameters can be stored.

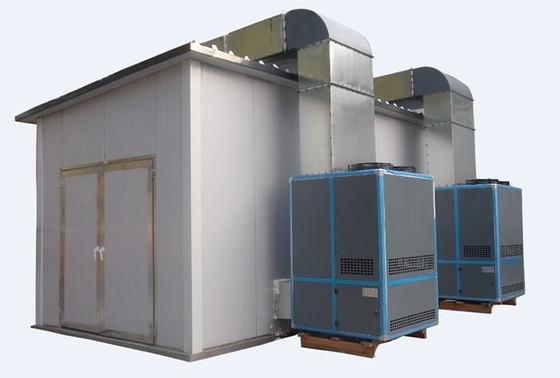

Equipment pictures:

Our service

Service before sell:

----Provide relative technical data for help equipment selection

----Running pilot test

----Offering advice for equipment selection, material analysis

----Provide flow chart, basic drawing

----Provide technical design

Service in sell:

----Provide factory layout according to contract

----Manufacturing ordered equipment according to the related standard

---- A presentation report of manufacturing situation will be offered every 15days

---- Tracking and supervising in whole manufacturing and transporting period according to the contract requirement

---- Photo of wooden case will be offered, wooden case with standard shipping marks.

---- Photo of freight loading will be offered.

---- A record of detailed delivery list will be offered

---- A record of detailed freight loading list will be offered

---- All of wooden case will be marked serial number, all of attachments will be marked serial number, convenient for client's clearing

Service after sell:

----Send service engineer for help instruct installation.

----Send service engineer for running test at site and training the operator

----Help client for maintenance and repair

----Provide one year spare part

----Quality warranty for two years after sell

Packing and delivery

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!