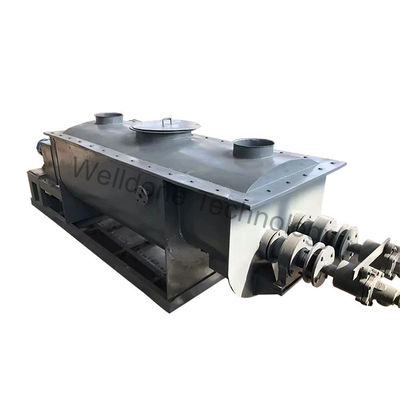

1. The residence time of materials is adjustable, which can handle materials with high water content and obtain materials with very low water content;

2. Typical conduction drying method, energy saving, large conductivity coefficient, high thermal efficiency, energy saving 30-60% more than the usual convection drying.

3. Because all the required heat is supplied by the hollow blades and jackets, in order to reduce the exhaust humidity, a small amount of hot air is added, the dust entrainment is low, the exhaust gas is easy to handle, and no auxiliary equipment such as dust removal is required.

4. The paddle has self-cleaning ability. The blades rotate in opposite directions, and the two inclined surfaces of the blades repeatedly stir, compress, relax and push the material, so that the page has a unique byte capacity, the heating surface is constantly updated, and the heat transfer coefficient of the blade dryer is higher than any other conduction. Drying method.

5. The heating medium is also introduced into the stirring blade, so the heat transfer area per unit volume of the dryer is larger than that of the general indirect heat transfer dryer.

6. The range of processing materials is wide. Due to the self-cleaning effect of the heating surface, most materials with high water content or viscous paste can be processed smoothly without returning to dry materials.

7. The amount of material stored in the dryer is very high, about 70-80% of the cylinder volume, the effective heating surface per unit volume is large, the equipment is compact, the volume is small, and the area is small.

8. It can be easily combined with other drying methods to form an efficient dryer, giving full play to their advantages and obtaining better economic and technical indicators, such as paddle-tray combination, paddle-flash combination, etc.

9. It can be operated under vacuum, solvent can be recovered, and volatiles of high boiling point viscous materials can be evaporated and removed.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!